Where's the Beef?

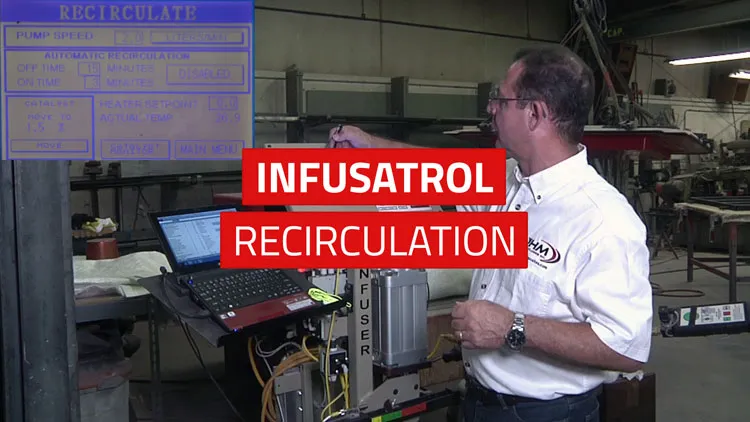

Every stroke of your injection pump costs you money. When operators manually adjust batch controllers for each mold change, those extra counts add up fast. Resulting in wasteful resin usage, unnecessary part rework, and mold strain!