RTM Process Questions Answered

- What is Resin Transfer Molding?

- How does the RTM process work?

- Is RTM suitable for high-volume production, or only low-volume?

- What are the primary advantages of RTM over open mold techniques?

- What is RTM Lite, and how does it differ from standard RTM?

Resin Transfer Molding (RTM) Process

Each company who enters into the resin transfer molding processes does so with numerous expectations and personal perceptions, as well as, experience.

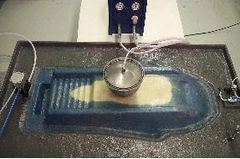

Most who have not been intimately involved in closed molding for many years have many questions of just what is happening inside the mold as the resin flows, the RTM Lite process with the “see through” upper mold half has been very valuable in answering many questions those new to closed molding have asked.

The introduction of the light RTM process, as originally adopted in France as the “ECO” process which was a process developed as an environmentally friendly low cost closed molding process, which is well suited for low production volume as so common in the European community.

This ECO process was built on the design features of a lite weight “see through” upper mold half.

Once this tool design and process method was introduced here in North America the name was recognized as the RTM Lite process.

The primary promoter of this process in North America has been Chomarat company from France as a means to advance the growth of the closed molding processes and the use of their fiberglass reinforcement ROVICORE, so much of the thanks is owed to Chomarat for their efforts in bringing the RTM Lite innovation to North America.

While the advantage of seeing through the mold allows the molder to actually "see" the resin flow during the injection process, which speaks volumes in advancing the understanding of just how the resin actually fills the mold, it does so at a price.

In order to see the resin we must build the upper from clear gel-coat, initially this was a MAJOR stumbling block for the RTM Lite process as the original clear tooling gel-coats were very rigid and crack very easily.

Recent innovations from the gel-coat suppliers has dramatically improved this concern, yet the clear gel-coats still do not perform as well as the more conventional solid color tooling gel-coats.

Further, the laminate of the see through upper, must be generally no greater in thickness then 3/16" (~.180″ or 4.5mm) in order to still maintain the clarity needed to see the resin flow.

Tooling of this thickness will perform well for very low to low volume production especially on generally flat shapes.

Yet, complex shapes, especially those with solid core materials require a molding staff who pays CAREFUL attention to detail, in order to prevent the mold from being damaged during the molding process.

It should be noted that the originators of the ECO or RTM Lite process live in a culture in which a higher level care is taken by the operator then common here in North America, this not a slight on the North American molding operator, we here are focused on VOLUME in our production, in Europe there is commonly lower volume and thus the culture is not so hurried as is the case here. In any event, light weight tooling will perform well if very careful attention is paid to all aspects of molding process. This is to mean that details such as gel-coat application, fiber loading, core placement, mold halves registration to each other during closure, amount of flange vacuum, and cavity vacuum levels all must be carefully controlled, while this is true of any of the vacuum assisted closed molding processes, it is especially true of the RTM Lite process when the upper mold half is built to a standard which allows for the resin to be seen as it fills the mold.

For the last 4 years JHM Technologies has been offering RTM Lite and ZIP RTM tooling which is built with added strength and design features that perform to a higher level of performance then the conventional "see through" RTM Lite tooling.

Our focus has been on tool life and production performance, while we may not have given enough consideration to the fact that many are just entering the closed molding environment and can benefit from the learning one receives from actually watching the resin flow during the injection.

Further, the majority of the molders who begin with their conversion into closed molding do so with choosing one of their "lower volume" parts, so the conventional RTM Lite tooling standard will perform well, especially if added care is provided in the molding process.

It should be noted however that building a more rigid upper mold, built with conventional tooling materials and added stiffening structure will OUT PERFORM the lighter “see through” mold.

Recently, I received a call from one of our long term customers who called mainly to say hi and to ask what is new in the industry. During our conversation we discussed many tooling standards in use today, one of his comments I thought was rather profound and further supports this article. He being a longtime closed molder who has multiple plants throughout the USA, and has been had many different forms of closed molding running in production for many years. He commented that they had started with the "lite RTM tooling standard" one where his operators could watch the resin flow, then they moved to what they call "Not so Light RTM" in which they too have added tooling structure and more conventional tooling materials to their tooling designs.

Keeping in mind that the MAJORITY of the cost in building the mold is NOT the materials it is the labor and time especially in the proper application of sheetwax, it is not a major cost impact to add some stiffness and use conventional tooling materials when building RTM Lite tooling.

The most profound change I have seen in the closed molding processes in the last 25 years has been the change from center injection to perimeter injection.

That is to create a CONVERGING flow from the standard as it had been for the last 30 plus years of a DIVERGING flow path.

This change came about from the introduction of the RTM Lite tool design.

This what might appear as a subtle change is the most radical change in recent closed molding history.

Keeping with that change and using then conventional tooling materials, with about 30% of the tooling structure as common to previous RTM tooling we have now a more robust closed molding process, with less scrap and more consistent part thickness then we had with the conventional RTM processes of the past.

Today, JHM Technologies offers three types of tooling structure to accommodate all levels of experience and production needs to their customers.

The first level is a "BASIC" level one built with all of the of the latest flow channel details to enhance even and uniform resin flow 360 degrees around the mold perimeter, as well as, can be fitted with either replaceable “tubes” or the latest in Automatic injection ports or vents. The ability to "see through" the upper is maintained to allow the new user the ability to evaluate the mold process as well as train their molding operators on troubleshooting their molding process. The Basic tool is made of high quality Vinyl Ester gel-coat and hand laid fiberglass reinforced Vinyl Ester laminate. Additional backing structure is added using steel box tubing as needed for stiffening and operator handling. The Basic tool is capable of producing the same level of part quality as either the "MAGNA" or "CONDITIONED MAGNA" series of tooling, the only compromise is that the BASIC series of tooling requires a bit more care and will not produce at the same rate as the MAGNA series.

The second level is the "MAGNA" series, while maintaining each of the key design details as found on the BASIC level, we have added conventional Vinyl Ester tooling gel-coat for added durability, then we hand lay the first skin layer to make absolute certain there are no voids behind the tooling gel-coat, the bulk laminate is then hand laid from fiberglass reinforced "filled zero shrink" resin.

This laminate is then "ribbed" with cored reinforcement as needed depending on the part geometry. The final backing is an engineered light weight "truss" of steel box tubing which provides optimum tooling structure with absolute minimal weight and cost. The MAGNA series of light weight closed molding tools are proving to provide the highest level of performance any where in the industry today. While maintaining optimum performance the cost and lead-time to produce a MAGNA series mold is very comparable to that of a conventional RTM Lite mold in the market today.

The third level is the "CONDITIONED MAGNA", the added feature of the Conditioned Magna is internal 3/8" copper water lines to maintain the optimum tool temperature during the injection and cure process.

The construction materials of the Conditioned Magna series tooling are Vinyl Ester tooling gel-coat, followed by a fiberglass reinforced hand laid vinyl ester skin coat, this skin coat is followed with a proprietary fiber lay-up made of various engineered fiberglass materials, then the entire laminate is vacuum infused with vinyl ester resin to create a laminate thickness of a minimum of .320" having a fiber loading of 55% by weight as a minimum standard.

With the added temperature control and vacuum infused vinyl ester laminate, the Condition Magna series tooling is providing optimum production cycle times for even the most demanding molding applications. Thick parts with high surface finish requirements are no concern for the Condition Sherman series of tooling and even with the all of the added features of the Condition Magna series tooling the final cost is normally less then a 35% premium over the Basic series tooling.