Resin Transfer Molding (RTM)

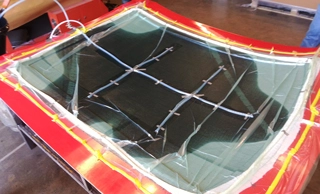

Light RTM (LRTM)

Silicone RTM (SRTM/RSB)

Vacuum Assisted RTM (VARTM)

With a full range of composite and aluminium tooling services JHM Technologies, Inc. has helped closed molders world wide achieve their tooling goals! JHM Technologies, Inc. is there to for you every step of way. Using our 80 years of combined tooling experience in order to help you make the right tooling decisions. From choosing the process that best fits your requirements—RTM, LRTM, VARTM, or reusable silicone bags (RSB). Properly designing your tool for pattern creation. Building your tool using our in-house tooling center. And finally, completing your build with our "commissioning part" proving the tool build.

JHM Technologies, Inc wide array of hands-on industry experience in automotive, medical, aerospace, home furnishings, sports, and security applications provide you with real experience. Contact us today to find out how you can achieve your tooling goals!